Diamond core bits are generally made with drilling solid rock in mind. Rock may be broken, hard, abrasive, etc., but will usually make its way up into the core tube en route to the geologist’s core table. For this most common formation which drillers are called upon to sample, a normal coring bit is used (see photo 1).

The main concern in drilling most rock formations is how to drill faster at a lower cost. Development of the regular coring bit will concern itself with flushing cuttings away from the bit, extending bit life, taking pressure off the bit.

At times, formations are encountered that are not easily recovered. These may include sand, certain clays, and other soft rocks. Often, geotechnical investigation of soils and concrete structures will require that very soft, non-competent formations be drilled. Some ore zones also occur in very unstable formations in seams, or veins, which are very difficult to recover intact. In this instance, core recovery, which is always important, can become crucial.

If drilling results indicate a low grade of ore caused by a low or otherwise poor level of core recovery, an exploration project could fail, leaving a viable deposit behind.

There are a couple of issues to consider when drilling these difficult formations. First is flushing. The bit requires that fluid be pumped from the inside out to carry away cuttings and to cool the bit. Failure to do so will result in immediate bit failure.

When the drilling fluid comes in contact with the sample, as it passes through the inside gauge of the bit into the lower end of the core tube, it is under high pressure, owing to the small space it has to go through compared to the relatively wide annulus between the inside of the core barrel and the outside of the core tube. This causes erosion to the sample that can cause it to be flushed out the front of the bit, instead of into the core tube.

To combat this erosion, drilling muds have been developed which basically change water into a thicker, more slippery fluid that will not (theoretically) penetrate soft formations. This is the case at low flow rates and under low-pressure conditions. The high spin rate of diamond drill bits, coupled with the pressure required to pass the fluid along the core and out the front of the bit produces a phenomenon called “shearing.” When this happens, the drilling fluid loses its viscosity, increasing the erosion of the sample and washing it out the front of the bit again. This process is accelerated when small loose stones in the formation start rolling around in the face of the bit like iron balls in a rolling mill.

Face discharge

Over the years, a lot of development went into producing bits that could reduce the flow rate of fluid coming into direct contact with the sample. These are the face discharge bits (see photo 2).

There are numerous variations of this design, but basically, the idea is to have the majority of the drilling fluid pass through the holes in the front of the bit for flushing, with a small portion coming through the inside gauge to provide cooling.

While better than a normal coring bit, face discharge bits have the same built-in problem. Even though less fluid is passing through the inside gauge, it still passes through under high pressure, contributing to the fluids shearing.

A lot of investigation has gone into matching TT and HQ3 core lifter cases (see photo 3) with predetermined distances back from the bit, cutting small notches into the lifter cases to enable them to practically sit on the bit, using triple tub designs, for example. The HQ3 Core Lifter Case has a narrow portion at its extreme end to allow a tighter fit than a regular lifter case. This causes more water to exit through the holes and less through the inside gauge of the bit. TT designs have an even larger pilot area turned down to fit even tighter into the face of the bit. Matching different types of bit designs with the HQ3 and TT combinations have produced varying job-specific results. Test results may vary, depending on drilling conditions. Radical improvement is rare, but not impossible.

Lateral discharge

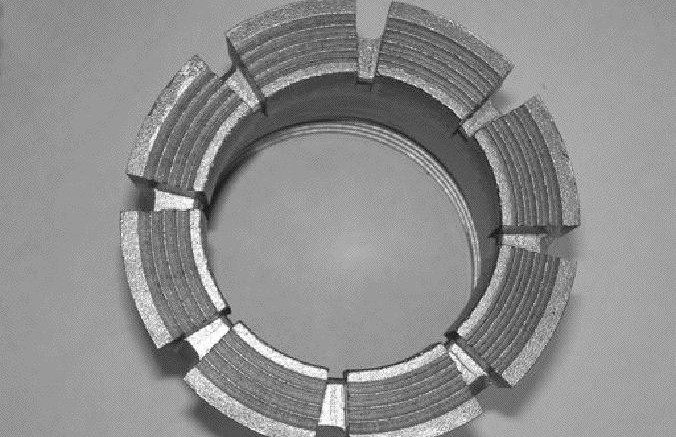

Radical improvement has been quantified using what is called the lateral discharge, or sand design bit (see photo 4). Arguably the single greatest advance in core recovery bits in recent years, this bit was initially developed for drilling diamond pipes in the Canadian Arctic, where good core recovery is essential.

Tests in soft sand and gravels in other parts of the world have held up the initial good results. In some cases, core recovery rates have improved from nearly zero to nearly 100% simply by changing to this bit. Of course, this dramatic result is not going to be obtained on every project, but results are generally good.

The major difference between this bit and the face discharge design is the size of the holes in the bit. In the sand design, it is as if the holes have been cut right out to the middle of the bit. It may be more correct to say that the inside waterways have been cut out to the edge of the bit blank, but the result is the same.

Drilling fluid pumped through the bit encounters less resistance than in any other previous bit design. This helps reduce the effect of shearing, which, along with the lower water pressure of the fluid on the actual core sample, enables it to slide into the core tube with far less erosion.

These bits are available in regular double tube, as well as triple tube for geotechnical drilling, and come in a variety of matrixes. Positive results are usually obtained immediately, with no experimentation necessary.

The major difference in drilling technique between these bits and classic face discharge is that with face discharge, the idea is to pump the drilling mud slowly and also to advance slowly. With the sand bit, fluid should be pumped at an increased volume and the bit advanced as quickly as possible, staying within normal limits of rotational torque.

As ground conditions and drilling technique are constantly changing, it can be hard to quantify results with core recovery products. Job-specific results that have no application on other projects can seem to be the answer, but objectivity is essential and exceedingly difficult to obtain. Experiment and learn.

— The author is a technical representative of Atlas Copco Exploration Products in Elko, Nev. www.atlascopcoexploration.com. He has worked for more than three decades in the drilling business in Canada, the U.S., Asia and Peru, including seven years at Newmont Mining’s Yanacocha mine, which is known its inherent problems with core recovery.

ALL PHOTOS: ATLAS COPCO EXPLORATION PRODUCTS

Be the first to comment on "Some bits about diamond drilling"