Not so long ago, in situ oilsands production was little more than a dream in the eye of Alberta’s petroleum producers. Years of government and industry-funded research cracked that nut with the development of steam assisted gravity drainage (SAGD) that has created a multibillion-dollar industry paying dividends to both producers and governments for two decades.

A new group of entrepreneurs and technology developers hope to repeat that formula to create Alberta’s next booming sector that could ride the wave of the transition to clean energy and energy storage.

E3 Metals (TSXV: ETMC; US-OTC: EEMMF) is leading the charge to usher in the new era leveraging technology developed at the University of Alberta combined with oil sector expertise to extract lithium from subsurface brine.

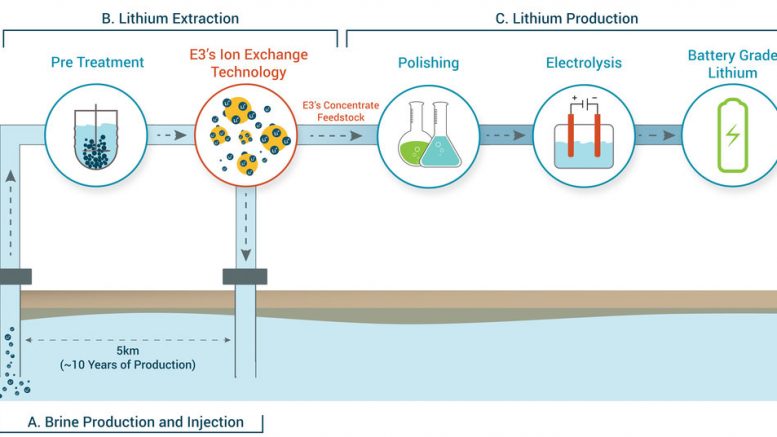

The company would essentially replicate conventional oil production; only rather than separating oil out of the subsurface fluids it would extract lithium. Many of Alberta’s increasingly depleted wells already produce up to 95 per cent brine that is pumped back underground after the oil is separated — E3 would simply target lithium instead of crude.

The four-year-old Calgary-based company crossed a major milestone recently with the investment of Philadelphia-based Livent Corp. (NYSE: LTHM), the world’s largest pure play lithium producer and a leader in lithium extraction technology with operations around the world. Livent pumped US$5.5 million into a joint technology development project will see a pilot plant to fruition and gives Livent the option to acquire 19.9% of E3 Metals thereafter.

E3 Metals has amassed mineral rights in the lithium-rich Leduc formation of central Alberta and hopes to be producing 20,000 tonnes a year of lithium carbonate equivalent by 2023 — coinciding with an expected crunch in the supply of lithium worldwide. The plant could scale up to 50,000 tonnes a year and the model could be replicated across E3 Metals leases in future years.

“Demand for lithium is soaring,” Liz Lappin, E3 Metals’ VP corporate affairs and exploration, and president of the recently formed Canadian Lithium Association, told a recent lithium workshop at the University of Calgary. Annual lithium demand of around 300,000 tonnes is set to jump to a million by 2025 and two million by 2030, representing “unprecedented demand for lithium really tied to electric vehicle growth,” she said.

“The second piece of this is that Alberta has lithium — a lot of lithium. We actually have as Alberta a real competitive advantage when it comes to developing that lithium, because we have a head start in terms of our understanding of geology, and the skills and knowledge that we have in this province. We understand wells and pipelines and many of the things that we use to develop oil and gas. There is a real parallel there.”

But like any industry that’s new and emerging, it has its challenges, she said. Alberta’s so-called petrolithium cannot be developed using traditional hard rock mining or salar [salt flats evaporation ponds] extraction techniques. The sector must perfect and scale new technologies to extract lithium from brine. Access to capital is a major challenge. And there remains uncertainty around the province’s regulatory framework. Right now, the sector needs “courageous policy,” Lappin said.

“But this might be a familiar story to some of you — for those of you familiar with SAGD, a technology that was developed back in the 80s,” she told the Alberta’s Lithium Ion Battery Supply Chain Opportunity workshop. “That was at a time when we couldn’t access deep oilsands economically. SAGD was just an idea. And there was a courageous group of innovators that went forward and developed an underground test facility and really blew all of the estimates out of the water with respect to performance and unlocked what was known to be an absolutely massive resource.

“This is something that I see as a real parallel to what we can do in this province with lithium and I have a lot of confidence in Alberta’s entrepreneurial spirit, combined with the pace of innovation. Alberta is looking honestly at an absolutely massive opportunity to compete in this industry.”

The sector could help revitalize an oil industry battered by the deepest downturn in a generation. “We are looking at potential resource revenues and jobs — not just any old jobs, but jobs that are high quality and really aligned with our existing skill sets in the province.

“And we also have the potential to produce some of the world’s most sustainable lithium,” she added. “I think that we can really leverage that green brand to our advantage as we move forward and diversify our resource economy.”

The race is on

There are a handful of other local companies chasing the lithium-from-brine prize. Purlucid, in partnership with MGX and Eureka, has developed molecular sieve/ion exchange technology. LiEP Energy is using an electrochemical technique (at lab scale prototype stage working on field/pilot demonstration), while Summit Nanotech is at lab scale with membrane and nanoparticles technology.

Prism Diversified, whose permits overlie the well-developed Devonian reefs that fringe the Peace River Arch in northwest Alberta, is moving ahead with a technology partner using LiREC extraction technology with production operations anticipated in 2021.

Other regions are also racing to develop new lithium production projects in time to capitalize on the looming supply shortage expected in the next three to five years, using some form of ion-exchange, nano-filtration or solvent extraction technology.

In Arkansas, Standard Lithium (TSXV: SSL; US-OTC: STLHF) is working to extract lithium from brine produced in the production of bromine with a technology and process thought to be similar to that developed by E3 Metals. It is starting up a 20,900 tonnes per year demonstration plant. A preliminary economic assessment found it could produce battery grade lithium carbonate for around US$4,300, at a time when the average selling price was US$13,500.

“That’s a good proxy for Alberta because it’s a resource that’s coming out for another reason. It’s not oil, it’s bromine, but it’s the same sort of philosophy. And they’re deploying very similar technology to what we will look to deploy here in Alberta,” said Chris Doornbos, E3 Metals founder, president and CEO. “It’s about a billion dollar project… So the numbers are pretty big.”

In California there is a long and checkered history of attempts to extract lithium from the Salton Sea area that is entering a new wave of activity, in combination with an uptick in geothermal development. The area is not only a geothermal hot spot, but considered to be one of the largest known sources of U.S. reserves of lithium. Like the sector in Alberta, producers would extract lithium from brine already brought to the surface before it is re-injected underground. By utilizing clean geothermal energy, its production would also have a low environmental impact.

After geothermal flat-lined for several years, three companies signed contracts for two geothermal plants in January in the state which has mandated 100 per cent climate-friendly electricity by 2045. One of the companies, Australia’s Controlled Thermal Resources, plans to piggyback lithium extraction to its plant in hopes of creating a major new domestic source — it is seeking to produce 15,000 tonnes by 2023 and ramp up to 75,000 tonnes by 2027.

California geothermal company EnergySource, which has a patented selective adsorbent lithium extraction process, operates a pilot facility jointly owned by Chevron Corporation and Mercury NZ Ltd. The company’s chief operating officer, Derek Benson, told the Los Angeles Times in October that a commercial extraction facility could produce 16,000 tonnes of lithium carbonate equivalent a year, with the potential for about 100,000 tonnes if other Salton Sea geothermal plants adopted the company’s technology. The company estimates one commercial plant could generate US$85 million in benefits to the local economy.

But there have also been failures. Technology start-up Simbol Materials came close enough to production that Tesla offered to buy it for US$325 million in 2014 — and there was speculation Tesla might build its battery gigafactory in the area, before choosing Nevada — before Simbol went out of business.

Warren Buffett’s Berkshire Hathaway Energy, owner of 10 of the 11 geothermal plants in the area, has also attempted to find a partner for lithium production. It continues to work with the federal government to improve the technology.

In February, Bill Gates-led Breakthrough Energy Ventures was among those leading an investment round of US$20 million for California startup Lilac Solutions, which uses ion-exchange beads to selectively remove lithium from oilfield and geothermal power plant brines. In Europe, Vulcan Energy Resources Ltd. plans zero-emissions lithium extraction facilities tied to existing geothermal power plants.

Oil and gas synergy

Alberta’s oil and gas heritage presents a number of advantages for direct lithium extraction (DLE) technology companies like E3 Metals. Thousands of wells have intersected lithium prospective reservoirs and historic seismic datasets and production records are available, reducing exploration costs and development risks. There is access to extensive oil and gas infrastructure, from roads and well pads to pipelines and power lines that enable companies to reduce their land disturbance. Companies may be able to utilize existing surface leases that have already gone through environmental assessments and regulatory approvals. Selectively revitalizing oilfield infrastructure where conditions allow could also assist in the remediation of end-of-life and abandoned wells.

There is also an existing workforce whose skill sets are easily transferable, from engineers and geologists to drillers, project managers and construction workers. And the expertise exists to move vast volumes of high salinity brines, as will be required by DLE production methods. In some cases companies can take advantage of already flowing brine or already drilled wells to produce lithium from brines.

E3 Metals estimates it will need to move more than 100,000 cubic metres of water a day for a 20,000 tonne per year lithium production facility. “Getting this [much] brine to a lithium processing facility is what we do in Alberta every day,” points out Doornbos. “These skill sets are in oil and gas — we’re drilling wells, we’re putting pipelines to production facilities already.”

The resource is plentiful, too. The Leduc is estimated to contain tens of billions of litres of lithium-bearing brines and has maintained substantial flow rates for decades.

E3 Metals estimates Alberta to host one of the largest sources of lithium globally and claims to hold the seventh largest company lithium resource — 6.7 million tonnes inferred lithium carbonate equivalent with 34% of total permit area delineated — with over 1.3 million acres of permits for development.

“This reservoir in Alberta is absolutely massive,” Doornbos told a recent webcast. After scaling its pilot plant to 50,000 tonnes per year, the company estimates it can produce for 35 years, as well as scale to other areas across the expansive reservoir.

New technology

But while the absolute numbers are high, Alberta’s lithium resource is relatively low concentration, necessitating new technology to economically extract it.

E3 Metals’ ion exchange technology works as a molecular sieve, Doornbos said. “As the brine flows over a solid chemical that we have developed, and that is our IP [intellectual property], the lithium absorbs onto this chemical,” resulting in up to 99% recovery of lithium from the water. “Every so often you have to wash off the lithium. So we use a proprietary wash agent to strip the lithium off the chemical. This strip also rejuvenates the chemical so we can reuse it. We can concentrate from 80 milligrams per litre, which is our average grade, to over 5,000 milligrams per litre in our concentrate solution.”

Because this material has such high selectivity for lithium, E3 also removes over 99% of the impurities. “And this is incredibly important, because at the end of the day, you’re taking a low grade lithium brine, 80 milligrams per litre and you’re converting it into a pure lithium solution, 99.5% lithium hydroxide or better to sell into the battery market.

“So that is a series of steps to concentrate it and purify it. Because our technology does both in one step, it has a huge amount of value that it’s going to potentially add to this project, and it’s what we believe is going to be the tipping point.”

Livent deal

Doornbos calls it an Alberta solution developed to lab scale with the support of federal and provincial grants, but now the company is at a stage where “bigger amounts of capital are required to do bigger things. And without that capital, there’s no industry.”

Hence the Livent investment. “It was critical because they’re now paying for that pilot plant. But it’s come at some sacrifice to E3 Metals. We’re going to give them [an option for] 20% of the company for that investment. And they’re going to get to be able to use this technology in their process. And that’s not something we gave up lightly or necessarily wanted to give up at this stage. But we needed the capital to get through the next hurdle, which is proving this in a pilot in Alberta.”

But along with Livent’s investment comes its own considerable expertise, he stressed. “They’ve been very supportive of the company on the technical side of things. It really de-risks our technology scale-up and accelerates the timeframe for us to get into production… That’s why we went to them. They’re experts, absolutely experts, in technology development for this new process. They’re bringing a lot of that to the table and therefore to Alberta, because all of this work is designed to get Alberta on the map as a producer, and they are here to help us do that.”

Road to net-zero

Greenhouse gas emissions are becoming an issue in lithium production, an issue E3 Metals wants to deal with from the start. One recent study found that between five and 18 tonnes of CO2 were produced per tonne of lithium, Doornbos noted. “The carbon footprint of lithium right now is a big concern,” he said. “We are aiming to get towards net-zero carbon lithium product.”

The company plans to deploy cogeneration power — utilizing both the electricity and the heat produced by natural gas generators — and to examine the possibility of harnessing geothermal power where the brine is hot enough. And it could go further to achieve true carbon neutrality.

“A goal for us for 2020 is to demonstrate the true viability of this [net-zero emissions]. And how we plan to do that is sequestering the CO2 back into the reservoir. This is a common practice in Alberta, used for enhanced oil recovery. And we can potentially even sell this CO2 to nearby operators.

“For us, [net-zero] is a very important piece of this, concerning how lithium is currently made and in the social consciousness of products going into electric vehicles.”

Unique opportunity

Eric Pelletier, director of the Canadian Lithium Association, told the workshop that the province could lead in developing a lithium production sector built on homegrown technology. “I think Alberta, with the talent pool that we have, is already at an advantage to capitalize on this. When you look at the underutilized workforce, the amount of expertise that is within the province, I think this is a huge opportunity, both on a resource standpoint, but also an opportunity to lead in a technology standpoint as well.

“Alberta, I think has a reputation for developing technology, not so much necessarily soft technologies, but hard technologies — processing technologies, advancements in pipeline integration, what have you. And I think this is the place to do that.”

While building a new sector may be the longer-term goal, Alex Grant, CEO and principal of Jade Cove Partners, said the more immediate priority should be to get at least one lithium extraction plant up and running to prove out the technology and get the ball rolling.

“We need one good looking project to work,” said Grant, who co-founded Lilac Solutions and now advises on technology strategy for lithium project developers. “At least start there [because] that’s something very practical you can do here.”

He lauded the Livent investment in E3 Metals as a major signal to the sector that new technologies can play an important role in meeting future lithium demand, but said more investment is needed to bring a thriving industry to the province. Compared to oil and gas industry investment, the price is reasonable, he said. For example, the federal government has pledged $12.6 billion for a pipeline expansion. Livent has a market capitalization of only about US$1.3 billion.

“For the price of an oil pipeline that might never be built, you could buy one of the biggest lithium companies in the world,” he told the Calgary audience. “There’s so much impact oil and gas could have on lithium. It’s such a small industry and [oil and gas is] such a big industry. [Oil and gas] has so much expertise that will be so valuable, like handling large quantities of fluids, like E3 has to do. It’s a really exciting time and I think oil and gas could have a huge impact in helping mature the lithium industry.”

Doornbos returned to the SAGD analogy. “The lithium potential in Alberta is the same as the oilsands, it has that same growth profile. It’s the same challenge — it’s an engineering challenge, it’s not a resource challenge. And so again, Alberta is probably the best jurisdiction to be developing a lithium project at the moment.”

— This article first appeared in The Daily Oil Bulletin, where Maurice Smith is a staff writer. The Daily Oil Bulletin is one of our sister publications and part of the Glacier Resource Innovation Group’s (GRIG’s) stable of publications.

Be the first to comment on "Alberta lithium startups aim to ease transition to clean energy economy"