“A lot of people talk about AI, machine learning, digital twins, as buzz words – as if AI can immediately solve all problems and there is a tool that will solve everything,” says Dr. Sohail Nazari, Andritz’s Global Vice President of Digital Transformation-Automation and Digitalization.

The road to achieving full autonomous operations can be full of twists and turns, but the key to start increasing autonomy is for operators to use all facets of automation and digitalization technologies introduced to a plant.

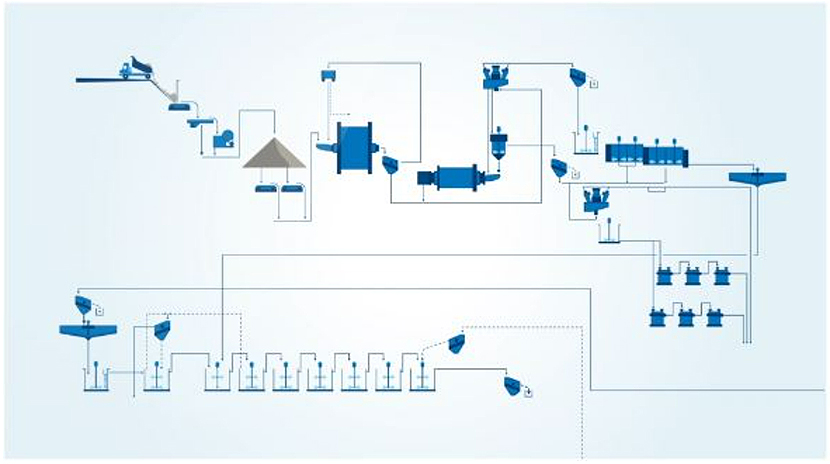

International technology group Andritz enables mining operations around the globe to bridge the gap from concept to implementation through to production with its suite of digital technologies – 196 in total successfully deployed at mineral processing plants around the world over the last 10 years.

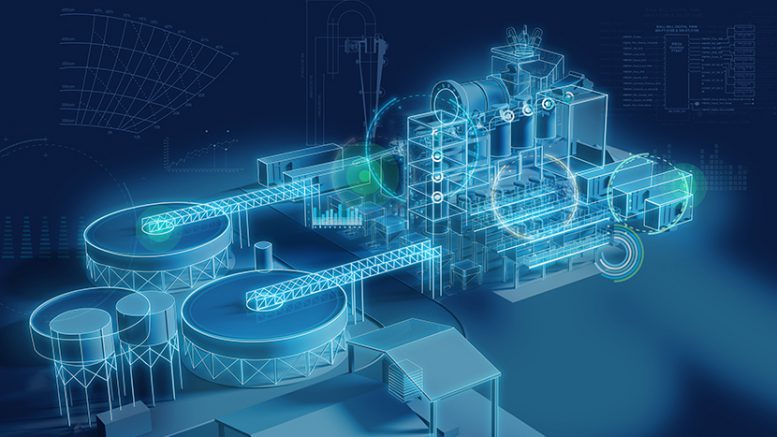

Andritz was among the first companies in the world that brought an applicable and practical method to introduce artificial intelligence (AI) into mineral processing – finding a way to train AI in the processing plan using digital twin technology to de-risk the implementation process.

Andritz technologies won the Disrupt Mining competition in 2019, attracting a $1 million investment from Goldcorp, just before it was acquired by Newmont, the world’s largest gold miner.

“We bring a diverse array of digital technologies to the mineral processing plant,” Nazari says.

“Incorporating a holistic solution of process optimization, asset management and operator training/knowledge management alongside instrumentation and digital infrastructure allows us to serve mining operators with a turnkey solution. Since we are vendor neutral, we work with all OEMs and equipment in a mineral processing plant.”

Comparing successful AI implementation to driving a car with its full range of technological features, Nazari highlights instances where the control room, equipped with navigation systems instead of a steering wheel, serves as the driver for autonomous vehicles.

Mining circuits improved. Credit: Andritz

“The truth is today’s cars come equipped with a range of technologies that gradually enhance driving performance. We’ve seamlessly integrated these technologies, such as navigation systems and adaptive cruise control, each contributing its own unique value. In fact, autonomous driving wouldn’t be feasible without first incorporating these essential technologies into the car.”

In a concentrator, there are many digital technologies that can step by step improve the operation.

Model predictive controller BrainWave as part of advanced process controls, the Metris platform that can aggregate data for complete asset management allowing advanced performance monitoring, and IDEAS simulation software for full dynamic modeling are some technologies that most benefit mining operations.

“We’re not in the business of selling software alone. Our focus lies in delivering comprehensive solutions and tangible results,” Nazari says.

In SAG mill operations, for example, there are proven model predictive controllers that can decrease the variability due to ore and push for more production, Nazari explains.

“What we do is we first decrease that variability by utilizing advanced process control, then we are able to go to the next level.

“In the next level of digitalization, we can use additional instrumentation to get more data, getting us ready to utilize more advanced technologies such as digital twin or machine learning.

“Just by incorporating advanced process control in a mineral processing plant, through decreasing that variability, we are able to increase 4 to 8% of throughput — increase 1% of recovery and decrease the power consumption,” Nazari says. “We are able to decrease the specific energy of the comminution area by anywhere from 5 to 12%.”

At the next step, when we add additional instrumentation, we are able to increase the throughput by an additional 2 to 5%.”

Incorporating AI and machine learning can be the subsequent step. Andritz solutions provide the necessary data for AI to learn about the mining operation’s surroundings, addressing the inherent challenge of employing data-driven AI algorithms: comprehending the environment and having accurate operational data.

“Instead of training the operators through operator training simulators, we started training artificial intelligence. This way we can solve the problem of not having the relevant data available,” Nazari says.

Andritz’s Operator Training Simulator utilizes a highly accurate dynamic model of the plant connected to the control system. It allows control room operators to interact as if they are interacting with the real operation, similar to a flight simulator.

“Using a digital twin of the process, we used reinforcement learning AI algorithms to get trained on how to operate certain unit area operations.”

In some cases, the utilized AI algorithm is similar to what is used in the video gaming industry, allowing each character to be aware of its surroundings.

“Now we took that algorithm and then brought it into the filter press operation to actually make the filter presses understand their surroundings. So now each filter press can decide when to wash, when to change the cloths, when to operate and when to go idle. To maximize the throughput and minimize the operating cost, they start communicating with each other.

“Constructing an autonomous operation involves more than a single technology; it encompasses a range of interconnected components applicable across various concentrators.

The process of minimizing variability, enhancing instrumentation, and driving increased production unfolds gradually, guided by experience, and ultimately leads to the desired outcome,” Nazari says.

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by ANDRITZ and produced in cooperation with Mining.com. Visit www.andritz.com for more information.

Be the first to comment on "JV Article: Path to autonomy in mineral processing with Andritz’s technologies"