In the future, mining companies will need to develop new business models that account for the increasing re-use and recycling of metals and minerals as the world moves towards a “circular economy.”

That was the key takeaway from a panel discussion on the circular economy at this week’s Global Mining Symposium. Moderated by Anthony Vaccaro, group publisher at The Northern Miner, the panel included Andrew Cheatle, non-executive director, Condor Gold (TSX: COG; LSE: CNR) and director, Troilus Gold (TSX: TLG; US-OTC; SKREF), and Elizabeth Freele, founder and CEO of 4P Solutions, a risk management and sustainability consulting firm based in Vancouver.

“Compared to the linear model, which is based on a take-make-waste economy and is the way that we’ve been living and using resources in recent modern memory,” Freele said. “The circular economy offers a sustainable alternative to the status quo and is predicated on providing for human needs within the natural constraints of finite resources.”

The circular economy, she explained, looks beyond resources as just being consumed and where their value is destroyed after a single use but embraces the principles of reprocessing, repurposing, and designing out waste and pollution.

The goal of the circular economy is to improve the productivity of these finite resources by allowing materials to function at their highest potential for as long as possible while also regenerating the natural systems we rely upon, Freele said.

“You can think of it as applying the waste hierarchy that you learned about in school, which is to reduce, reuse, and recycle before considering disposal,” she said.

Governments worldwide have started to adopt the circular economy model, including the government of Canada, Cheatle noted.

“When I was working with the Prospectors and Developers Association of Canada a few years ago, the Canadian government’s Canadian Minerals and Metals Plan included a substantial component of the circular economy in it,” he noted. “It was then that I realised how significant the circular economy would be to mining companies in the future.”

He continued, after initially viewing the circular economy as ‘anti-mining,’ mining companies are now increasingly building circular concepts into their strategic planning and modelling, with many companies already starting to recharacterize themselves.

He noted, for instance, that Anglo American (LSE: ALL), the world’s largest platinum producer, with about 40% of global output, is already starting to reimagine itself.

In a keynote speech at the Mining for Circularity event hosted by Coreo and the Circular Economy Leadership Coalition in collaboration with the Canadian government last October, Anglo American’s CEO Mark Cutifani said that there is a “strong rationale for us to engage with the circular economy that is strategic both from a planetary boundaries perspective and in order to support and accelerate our company’s ambitions.”

“If I look back over the years, we have characterized ourselves as a mining company, today we characterize ourselves as a metals and mining company, and tomorrow we could very well be categorizing ourselves as a materials solution company,” he added.

So, could the circular economy bring about the “end to traditional mining companies?” asked The Northern Miner’s Vaccaro.

“Even if a 100% circular economy were put in place tomorrow, the extraction of raw materials would not disappear overnight,” Freele said. “We see it accelerating at the moment to meet the increasing demand as the human race keeps on growing and continues to consume increasingly larger amounts of resources.”

In the future, however, she sees mining companies that produce virgin metals and mineral products having to compete with companies that use secondary materials which have been reused or recycled. “Investors and consumers are increasingly pressuring companies to disclose the ecological and social impacts of their products.”

In particular, the next generation of consumers will want to make sustainable and responsible purchasing choices. “They will want a small carbon footprint for the products they buy, they will want to know about the provenance of materials and any human rights abuses associated with them, and the impacts that products have on biodiversity,” Freele said.

For some mining companies, the future is already here.

In 2019, Nucor (NYSE: NUE), the largest supplier of steel in North America, sold 16.1 million tonnes of scrap into a highly competitive market with narrow margins and earned revenues of over US$22.6 billion, Cheatle noted.

“About 30% of ArcelorMittal’s steel is made using scrap instead of iron ore, and already half of the copper demand in Europe is being met by recycled material,” he said.

The chassis of Apple’s MacBook Air is now made from 100% recycled aluminium and, Freele said, this is just the beginning for the world’s most valuable brand (according to the Brand Finance Global 500 2021 Index).

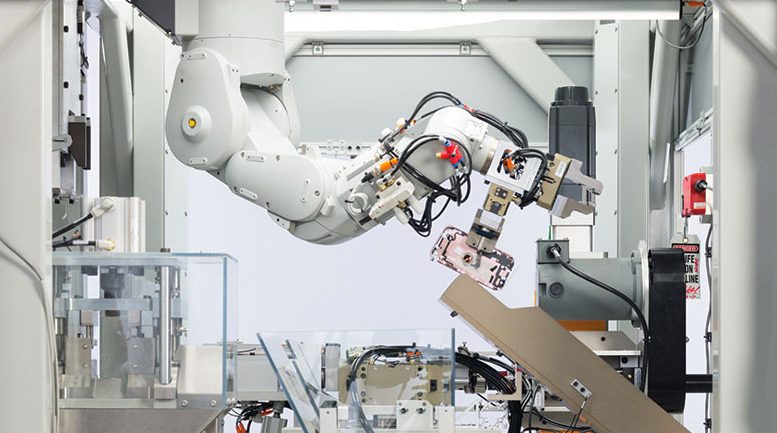

“The company has committed to manufacturing all their devices from materials that are recycled or supplied from renewable resources,” she said. Apple’s in-house disassembly robots are already capable of recovering 29 oz. of gold, 240 oz. of silver, and nearly 2 tonnes of aluminium for every 100,000 iPhones disassembled.

In a smartphone first, Freele noted that the iPhone’s Taptic Engine, which provides tactile sensations in the form of vibrations to users, now uses 100% recycled rare earth elements.

Be the first to comment on "The circular economy set to transform the mining industry, says panel at the Global Mining Symposium"