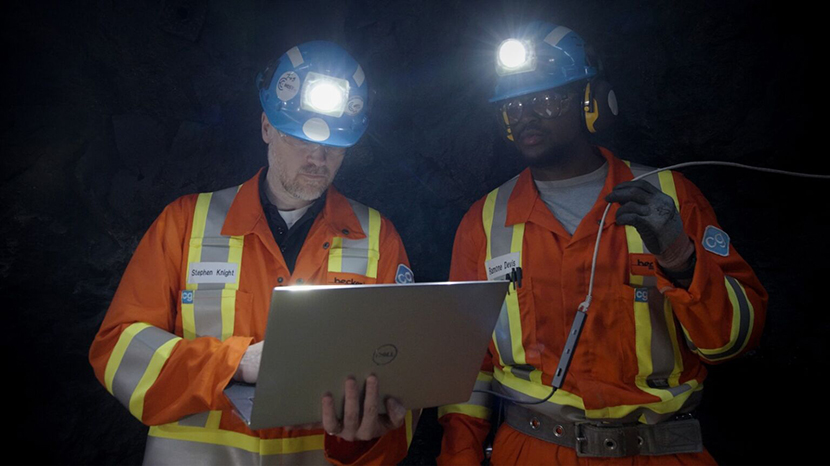

Most people never see what happens underground in the dark, noisy and cramped locations where mining equipment drills, digs and hauls. Companies that try to use surface technologies are bound to fail, according to Becker Mining Systems Canada CEO Albert Bower.

The German company’s local unit focuses on purpose-built engineering to drive product development, he says. It designs systems for the real conditions mines face – dust, humidity, vibration and confined spaces in a complex three-dimensional world that is largely hidden from sight.

“Each of our products is designed from the ground up for underground mining operations,” Bower said. “We’re unique.”

The division, headquartered in Sudbury, Ont. next to Canada’s most famous nickel-copper mines, incorporates how reliable connectivity is essential to safety and productivity. It’s building on the parent company’s 60 years of global industry experience offering integrated energy, automation, communications and transport systems. It knows how to operate on sites vertically and horizontally – often in environments filled with obstacles and decibels.

Bower also spoke with pride about Becker’s commitment to a field-first engineering approach. Becker combines system-level engineering with hazardous-area certifications and local project delivery.

The Canadian operation was formerly Varis Mine Technology which was founded in 1997 and joined Becker in the mid-2000s. Since then, the Canadian team has operated as Becker Mining Systems Canada, supporting sites across the country and internationally.

“The Canadian team provides engineering, project management, onsite commissioning, training and ongoing service – backed by the Becker Group’s global manufacturing and R&D capabilities,” the CEO says. “This blend of local responsiveness and global scale helps mines reduce integration risk, accelerate commissioning, and maintain operations more reliably.”

The company also actively engages in field testing and collaboration with Canadian innovation partners such as NORCAT, the Northern Centre for Advanced Technology, a Sudbury–based non-profit. It serves as both a mining technology innovation centre and an underground training and testing facility.

Becker holds at the core of its operating philosophy several views:

- All systems must offer the highest degree of reliability.

- Parts must be readily available if customers need them.

- The company tracks where each system is working.

- As new products are available, they can be replaced in existing systems without the need to exchange the entire system.

The company’s mission and vision are clear and deeply aligned. Becker has spent decades setting industry standards for efficiency, safety, and sustainability. Its mission is to help mining companies operate more productively and responsibly, while its vision is to shape the future of mining through leading-edge technologies. Becker says sustainability and mining can, and should, go hand in hand.

Becker’s solutions are designed to make mining not only more profitable, but also more environmentally responsible. Innovations like underground electromobility, Internet of Things integration, and predictive maintenance are at the core of this approach.

Becker provides a full range of mining solutions: communications (Leaky Feeder/LTE networks, remote sensing and blasting modules), proximity detection and collision-avoidance automation and fieldbus control, belt rip detection systems, energy distribution (explosion-rated switchgear, transformer-switchgear combinations and rugged electrical components), haulage and conveyance systems, and the Smartflow digital platform for operational visibility.

These product families are engineered to integrate with one another so customers can deploy coordinated, single-vendor systems rather than stitch multiple-point solutions together. It is an extensive line-up designed to boost efficiency, productivity and environmental stewardship across mining projects.

“We don’t sell individual boxes,” Bower says. “We deliver systems that work together. That one-vendor accountability shortens project timelines and reduces risk.”

The preceding Joint Venture Article is PROMOTED CONTENT sponsored by Becker Mining Canada and produced in cooperation with The Northern Miner. Visit www.Becker-Mining.com for more information.

Be the first to comment on "JV article: Becker aligns tech with site demands"